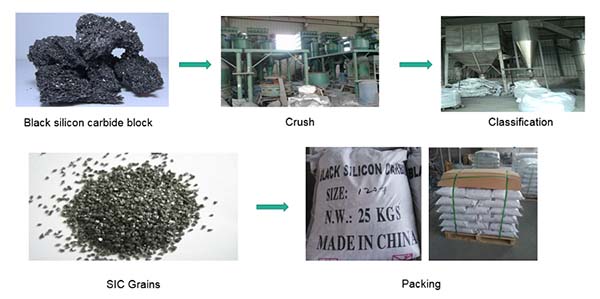

Black silicon carbide is made from quartz sand and smokeless acetylene as the main raw material. It is made via light resistance from hydro metallurgical, it is black opaque body hexagonal crystal and MOHS-hardness the 9.15, which is after diamond and boron carbide with crisp and sharp performance and certain degree of conductive heat.

Black silicon carbide is higher toughness than green silicon carbide with sic purity 98%, it have been used for processing glass, ceramic, stone, refractory materials, cast iron and other metal.

TYPICAL CHEMICAL ANALYSIS | TYPICAL PHISICAL PROPERTIES | ||

SiC | ≥98% | Hardness: | Mohs:9.15 |

SiO2 | ≤1% | Melting Point: | Sublimes at 2250 ℃ |

H2O3 | ≤0.5% | Maximum service temperature: | 1900℃ |

Fe2O3 | ≤0.3% | Specific Gravity: | 3.2-3.45 g/cm3 |

F.C | ≤0.3% | Bulk density(LPD): | 1.2-1.6 g/cm3 |

Magnetic content | ≤0.02% | Color: | Black |

Particle shape: | Hexagonal | ||

Grit designation | Mean diameter in um |

F12 | 1765 |

F14 | 1470 |

F16 | 1230 |

F20 | 1040 |

F22 | 885 |

F24 | 745 |

F30 | 625 |

F36 | 525 |

F40 | 438 |

F46 | 370 |

F54 | 310 |

F60 | 260 |

F70 | 218 |

F80 | 185 |

F90 | 154 |

F100 | 129 |

F120 | 109 |

F150 | 82 |

F180 | 69 |

F220 | 58 |

Black silicon carbide Application

The tungsten carbide grits is suitable for hard facing material.

1 mesh to 12 mesh: used for wear-resistance electrode and mace electrode;

10 mesh to 60 mesh: used for saw blade or play a role of wear-resisting welding in the metal surface.

2) Slicing of silicon carbide wafers

3) Rock and stone polishing and engraving

4) Slicing, lapping,and polishing glass and germanium wafers

5) Lapping of piston rings and gears

6) Grinding of nonferrous materials

7) Finishing tough and hard materials

8) Bonded abrasive tool applications

9) Glass etching and glass carving industries

Reviews

There are no reviews yet.