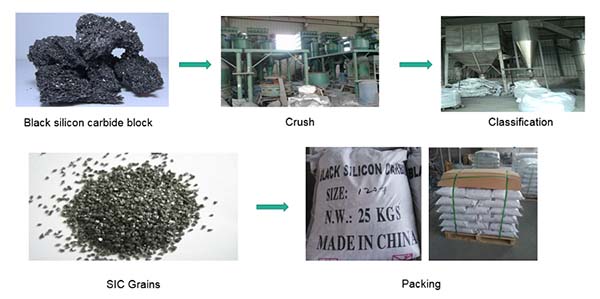

Black silicon carbide is made from quartz sand and smokeless acetylene as the main raw material. It is made via light resistance from hydro metallurgical, it is black opaque body hexagonal crystal and MOHS-hardness the 9.15, which is after diamond and boron carbide with crisp and sharp performance and certain degree of conductive heat.

Black silicon carbide is higher toughness than green silicon carbide with sic purity 98%, it have been used for processing glass, ceramic, stone, refractory materials, cast iron and other metal.

TYPICAL CHEMICAL ANALYSIS | TYPICAL PHISICAL PROPERTIES | ||

SiC | ≥98% | Hardness: | Mohs:9.15 |

SiO2 | ≤1% | Melting Point: | Sublimes at 2250 ℃ |

H2O3 | ≤0.5% | Maximum service temperature: | 1900℃ |

Fe2O3 | ≤0.3% | Specific Gravity: | 3.2-3.45 g/cm3 |

F.C | ≤0.3% | Bulk density(LPD): | 1.2-1.6 g/cm3 |

Magnetic content | ≤0.02% | Color: | Black |

Particle shape: | Hexagonal | ||

Grit designation | Mean diameter in um |

F12 | 1765 |

F14 | 1470 |

F16 | 1230 |

F20 | 1040 |

F22 | 885 |

F24 | 745 |

F30 | 625 |

F36 | 525 |

F40 | 438 |

F46 | 370 |

F54 | 310 |

F60 | 260 |

F70 | 218 |

F80 | 185 |

F90 | 154 |

F100 | 129 |

F120 | 109 |

F150 | 82 |

F180 | 69 |

F220 | 58 |

Black silicon carbide Application

The tungsten carbide grits is suitable for hard facing material.

1 mesh to 12 mesh: used for wear-resistance electrode and mace electrode;

10 mesh to 60 mesh: used for saw blade or play a role of wear-resisting welding in the metal surface.

2) Slicing of silicon carbide wafers

3) Rock and stone polishing and engraving

4) Slicing, lapping,and polishing glass and germanium wafers

5) Lapping of piston rings and gears

6) Grinding of nonferrous materials

7) Finishing tough and hard materials

8) Bonded abrasive tool applications

9) Glass etching and glass carving industries

PirojokDet –

darknet market links darknet market links

Pirojokshelp –

darknet sites dark web market list

Carlton –

A highly useful and well-explained article! This website consistently delivers great

content.

Here is my webpage: astrohvarna

Pingmok –

dark web market dark web link

DonDonWaf –

dark web markets darknet drug links

DonaldTax –

darkmarket url darknet market lists

Donaldphodo –

dark market list dark web marketplaces

DonDonabind –

darknet markets dark web marketplaces

DonaldTax –

darknet drug store dark market url

Rabyporma –

onion dark website dark web market

DonDonWaf –

darknet links dark web markets

Tolikplova –

darknet market bitcoin dark web

Donaldphodo –

dark web market urls darkmarket link

Pingcex –

darknet links darkmarket link

Pingmok –

darknet market list dark market url

Pingcex –

darknet markets onion darknet markets onion address

Pingmok –

darknet site darknet markets onion address

DonDonabind –

dark web market links dark web market urls

TolikFus –

bitcoin dark web darknet markets links

Pingmok –

bitcoin dark web dark web markets

DonDonabind –

darkmarket dark market url

TolikFus –

tor drug market dark market list

Donaldphodo –

darknet drugs darknet market

Pingcex –

darkmarket url dark websites

Pingmok –

darknet markets 2025 tor drug market

DonDonWaf –

dark market url darknet drug store

DonDonabind –

darkmarket list darkmarket link

Donaldphodo –

darknet marketplace darknet markets url

Pingcex –

dark web market links darknet markets 2025

Pingmok –

darknet drug links darknet links

Tolikplova –

darknet market darkmarket 2025

DonDonWaf –

darknet markets onion address bitcoin dark web

RabyInhek –

darknet market lists dark web marketplaces

TolikFus –

darknet markets darknet market list

Donaldphodo –

darknet markets 2025 dark market list

Pingcex –

dark market link dark web market urls

Pingmok –

darknet market links dark web link

Pingmok –

darknet market list bitcoin dark web

Rabyporma –

darknet market links dark web marketplaces

RabyInhek –

dark markets darkmarket list

Pingcex –

darknet drug market darknet market list

Pingmok –

dark web markets best darknet markets

Donaldphodo –

dark web market links darknet markets onion address

RabyInhek –

darknet markets darknet market links

Pingmok –

dark market dark web market links

Tolikplova –

dark web market links darkmarket 2025

Rabyporma –

dark web market links darknet markets onion address

DonDonabind –

darknet drugs darknet markets links

RabyInhek –

bitcoin dark web dark web markets

Pingcex –

darkmarket list darknet market links

Pingmok –

darknet markets url darknet market links

DonDonWaf –

dark web marketplaces darknet sites

Donaldphodo –

dark markets dark markets

Pingmok –

dark websites dark web drug marketplace

RabyInhek –

darknet market links dark websites

Pingcex –

darknet markets onion address darkmarket

Pingmok –

darkmarket darknet market lists

Donaldphodo –

dark market best darknet markets

RabyInhek –

dark web drug marketplace dark web sites

DonDonabind –

darknet drug market darknet drug links

Pingmok –

darknet markets onion address dark markets

DonDonWaf –

dark market url dark market list

Donaldphodo –

darkmarkets darknet site

TolikFus –

dark market onion darknet markets 2025

DonDonabind –

dark market darknet markets

RabyInhek –

dark web market dark market

Pingcex –

dark web markets onion dark website

Pingmok –

dark web market dark market url

DonaldTax –

dark web markets dark websites

Rabyporma –

darknet websites dark markets 2025

Donaldphodo –

darknet markets 2025 darknet drug links

TolikFus –

darkmarket url darknet websites

RabyInhek –

dark web market links bitcoin dark web

Pingmok –

dark web market urls darknet markets onion

Pingcex –

darknet drug store dark web marketplaces

DonDonWaf –

darknet markets onion address darknet sites

Donaldphodo –

bitcoin dark web darknet market

TolikFus –

darknet market links darknet drugs

DonDonabind –

darknet drug market dark markets

Pingcex –

dark websites dark web marketplaces

Pingmok –

dark markets 2025 dark market link

Rabyporma –

dark web markets darknet markets onion address

Donaldphodo –

darknet markets 2025 darknet site

DonDonabind –

darknet markets darknet markets url

Pingmok –

darknet market dark market onion

Tolikplova –

dark web sites darknet drug store

DonDonWaf –

dark web market darkmarket url

RabyInhek –

darkmarket url dark markets

Pingcex –

darknet market list dark web market

Pingmok –

bitcoin dark web dark web link

TolikFus –

darknet markets onion address darknet sites

RabyInhek –

darknet markets onion darknet market links

Pingcex –

darknet market lists dark market 2025

Pingmok –

bitcoin dark web darkmarkets

RabyInhek –

darknet market lists darkmarket 2025

Pingmok –

dark market darknet sites

Tolikplova –

darknet site darknet markets onion

DonDonabind –

dark web link darkmarkets

Donaldphodo –

dark markets 2025 darknet market lists

Pingmok –

darknet markets links darknet market links

DonDonWaf –

darknet drug market darknet site

Pingcex –

dark web marketplaces darknet markets onion

RabyInhek –

dark web market urls darknet market

Donaldphodo –

dark web link dark web market

Pingmok –

dark market link darkmarket

DonDonWaf –

dark market list dark market link

DonaldTax –

darknet links darkmarket url

DonDonabind –

darknet drug store darknet market list

TolikFus –

dark market darknet site

Donaldphodo –

dark web link darknet site

Pingcex –

darknet markets onion darknet drug links

Pingmok –

darknet drug store darknet links

DonaldTax –

dark markets 2025 darknet markets url

TolikFus –

darknet market lists darknet markets onion

RabyInhek –

dark web market links darknet drug links

Donaldphodo –

dark market list darknet drug market

DonDonWaf –

darknet drug store darknet markets

Rabyporma –

dark market link dark market

DonDonabind –

dark market link darknet drug links

Donaldphodo –

dark web markets darknet site

Pingcex –

darknet drug store darknet sites

Tolikplova –

darknet site dark market onion

DonDonWaf –

darknet marketplace darknet drug links

TolikFus –

dark market list dark web marketplaces

Pingmok –

darknet markets onion darknet drug store

Donaldphodo –

best darknet markets dark web market urls

Pingcex –

tor drug market darknet markets onion address

Pingmok –

dark market onion dark market list

Rabyporma –

dark market url darknet drugs

DonDonabind –

dark web marketplaces darknet markets

Donaldphodo –

tor drug market onion dark website

Pingcex –

darknet markets onion darknet markets 2025

Pingmok –

darkmarket url best darknet markets

Tolikplova –

darknet market links dark web market list

DonDonabind –

dark websites darknet markets links

RabyInhek –

dark web drug marketplace dark web drug marketplace

Donaldphodo –

dark market 2025 best darknet markets

Pingmok –

darknet drugs tor drug market

Tolikplova –

dark market 2025 dark web link

TolikFus –

dark markets 2025 darknet markets url

RabyInhek –

darknet markets links dark web marketplaces

Donaldphodo –

darkmarket darknet drugs

Pingmok –

dark markets 2025 dark markets 2025

Tolikplova –

dark market 2025 dark markets

DonaldTax –

darkmarket url dark markets 2025

KxyuWaf –

darknet markets links darknet market lists

Kxyuabind –

dark web market darknet markets links

WilliamIRmok –

dark web market list best darknet markets

PirojokDet –

dark web marketplaces dark market onion

Pirojokshelp –

dark markets 2025 darknet market

KxyuWaf –

darknet market links darknet marketplace

PirojokDet –

darkmarket list darkmarkets

Pirojokshelp –

darknet market lists darknet site

WilliamIRcex –

darknet market lists darknet market lists

Kxyuabind –

dark web sites darkmarket url

PirojokDet –

darkmarket 2025 darknet market links

Pirojokshelp –

darknet drug store dark market 2025

Kxyuabind –

darknet markets onion address darknet drug market

FNDavidInhek –

dark web link best darknet markets

Pirojokshelp –

dark market onion darkmarket link

Kxyuabind –

dark web markets darknet markets links

MarkNOphodo –

dark market 2025 darknet market links

FNDavidInhek –

darknet market lists dark web market list

Pirojokshelp –

darknet markets darknet markets onion

KxyuWaf –

darknet market darknet websites

WilliamIRmok –

dark market onion dark web market links

MarkNOphodo –

dark web drug marketplace dark web markets

FNDavidInhek –

darknet markets onion darknet markets links

PirojokDet –

darknet websites darkmarkets

Pirojokshelp –

best darknet markets darknet markets onion address

Kxyuabind –

darknet markets onion address dark web marketplaces

FNDavidporma –

dark web drug marketplace dark web market urls

FNDavidInhek –

darknet market lists dark web market urls

MarkNOphodo –

dark market onion darkmarket 2025

Pirojokshelp –

dark websites dark web sites

WilliamIRmok –

darknet market darknet markets

FNDavidInhek –

dark web market links dark web drug marketplace

Pirojokshelp –

dark web drug marketplace dark web markets

WilliamIRcex –

dark market darknet links

WilliamIRmok –

darkmarket list dark websites

MarkNOphodo –

darkmarket url dark web market list

Pirojokshelp –

darknet sites dark market 2025

WilliamIRcex –

darknet drugs darkmarket

MarkNOTax –

tor drug market dark web markets

FNDavidInhek –

darknet drug links darknet drugs

Pirojokshelp –

dark web market links darknet market links

KxyuWaf –

darknet drug market best darknet markets

WilliamIRmok –

darknet market links darknet markets onion address

FNDavidInhek –

onion dark website darknet links

PirojokDet –

darknet drug market darknet market

WilliamIRmok –

dark web market dark market 2025

FNDavidporma –

darkmarket list dark web markets

FNDavidInhek –

dark web market urls darknet markets

MarkNOphodo –

darknet market lists darkmarket list

Pirojokshelp –

darknet drug market darknet market lists

WilliamIRcex –

darknet market links dark web market links

Kxyuabind –

darkmarket list darkmarket link

FNDavidporma –

dark market list darkmarket link

FNDavidInhek –

darkmarket 2025 darkmarket url

Pirojokshelp –

dark web marketplaces dark markets

Pirojokshelp –

dark web sites dark web market

WilliamIRmok –

dark web market darknet sites

FNDavidporma –

dark market link darknet drug market

MarkNOTax –

dark market list dark web sites

FNDavidInhek –

darknet markets url dark web marketplaces

MarkNOphodo –

darknet market darknet markets 2025

PirojokDet –

dark market url dark web marketplaces

Pirojokshelp –

darknet market list darkmarkets

KxyuWaf –

darkmarket dark market 2025

WilliamIRmok –

darknet drug market darknet drugs

Kxyuabind –

darknet markets links darknet markets

FNDavidInhek –

dark web marketplaces darknet market lists

Kxyuabind –

dark websites dark websites

FNDavidporma –

dark market onion dark markets

FNDavidInhek –

dark markets darknet links

MarkNOphodo –

darknet markets onion dark web market

PirojokDet –

dark market dark market onion

Kxyuabind –

darknet site dark web market list

WilliamIRmok –

dark web markets darknet sites

FNDavidporma –

dark web market links darknet drug links

MarkNOphodo –

dark web sites bitcoin dark web

PirojokDet –

darknet site darkmarkets

WilliamIRmok –

dark market dark market link

Kxyuabind –

dark market link dark market 2025

Pirojokshelp –

dark web sites darknet market

WilliamIRcex –

darknet sites darknet markets url

Kxyuabind –

dark web drug marketplace darknet websites

FNDavidInhek –

dark markets 2025 dark web market

MarkNOphodo –

dark web market darknet markets onion address

PirojokDet –

dark web drug marketplace darknet market links

Pirojokshelp –

dark market url tor drug market

WilliamIRcex –

dark web market links dark market url

KxyuWaf –

dark web sites dark market link

MarkNOTax –

darknet markets url darknet drug market

PirojokDet –

darkmarket link dark websites

Pirojokshelp –

dark websites dark market onion

KxyuWaf –

dark web marketplaces dark web link

Kxyuabind –

darkmarkets dark web sites

FNDavidporma –

dark market list dark web market links

PirojokDet –

dark market onion best darknet markets

Pirojokshelp –

dark web market list dark web markets

MarkNOTax –

darknet websites dark market onion

FNDavidInhek –

dark market list bitcoin dark web

Pirojokshelp –

dark market dark market onion

FNDavidporma –

darknet market list dark websites

Kxyuabind –

dark web market urls dark web sites

Pirojokshelp –

dark markets dark web sites

WilliamIRmok –

darknet links darknet drug store

MarkNOphodo –

darknet drugs dark market 2025

PirojokDet –

darknet markets onion address darknet links

Pirojokshelp –

darknet drug store darkmarket 2025

Pingmok –

tor drug market dark web link

Donaldphodo –

darknet drug links onion dark website

Pirojokshelp –

darknet links darknet marketplace

Pingcex –

dark web marketplaces darknet drug store

Pingmok –

darknet markets darknet markets links

DonDonabind –

dark market 2025 darkmarket url

Donaldphodo –

dark markets dark markets 2025

Pingcex –

dark market onion darknet market list

Pingmok –

dark web market darknet websites

Tolikplova –

darkmarket link darknet markets url

TolikFus –

dark web drug marketplace darknet markets

DonaldTax –

dark market 2025 dark web marketplaces

Pingmok –

darknet marketplace dark web link

RabyInhek –

dark web markets dark market list

Donaldphodo –

dark market url darknet markets url

DonDonWaf –

darknet markets onion dark web marketplaces

Tolikplova –

darknet drug market darknet markets

Pingcex –

dark market 2025 dark websites

Pingmok –

darknet drug store darknet marketplace

DonaldTax –

darknet market dark market onion

Rabyporma –

darkmarket list dark web sites

RabyInhek –

best darknet markets darknet markets onion address

Donaldphodo –

darknet markets url dark market list

Pingcex –

dark web sites dark web marketplaces

Pingmok –

darkmarket list darknet websites

Tolikplova –

darknet markets url dark web market urls

TolikFus –

darknet market links best darknet markets

Pingmok –

darknet markets links dark web market links

DonDonabind –

darkmarket 2025 darknet websites

Rabyporma –

darknet market lists dark market list

KxyuWaf –

dark web marketplaces dark markets

Donaldphodo –

onion dark website dark market

PirojokDet –

dark market onion darkmarket url

Pirojokshelp –

darknet sites darkmarket 2025

Pingmok –

darknet market list darknet market list

TolikFus –

dark market 2025 tor drug market

KxyuWaf –

darkmarket link dark web drug marketplace

FNDavidporma –

darknet marketplace dark websites

MarkNOphodo –

darkmarket url darknet drugs

FNDavidInhek –

darknet markets url darkmarket

Pirojokshelp –

dark web market links dark market 2025

RabyInhek –

onion dark website dark web market urls

Pingmok –

dark market list dark web market

Tolikplova –

darknet site tor drug market

DonDonWaf –

darknet markets links dark web link

DonDonabind –

darknet websites darknet drug store

Pingcex –

darknet markets onion address dark web market

Pingmok –

darknet marketplace darkmarket list

Rabyporma –

darknet websites darknet site

FNDavidporma –

dark markets 2025 dark market url

PirojokDet –

dark web market darkmarket url

MarkNOphodo –

darknet markets url best darknet markets

FNDavidInhek –

darknet markets 2025 darknet site

Pirojokshelp –

dark web market list darknet market links

Pingcex –

darknet market darknet drug market

Pingmok –

dark markets 2025 darkmarket link

TolikFus –

dark web market urls dark market link

DonDonabind –

tor drug market darknet drug market

Donaldphodo –

dark market onion darknet market links

RabyInhek –

dark web link dark market list

MarkNOTax –

darknet markets links dark websites

FNDavidInhek –

darkmarket dark market 2025

MarkNOphodo –

dark market list darknet markets url

Pirojokshelp –

bitcoin dark web darknet markets url

Pingmok –

darknet market links darkmarket 2025

Tolikplova –

dark web market dark market url

DonDonabind –

darknet markets links darknet market list

TolikFus –

darknet site dark markets

RabyInhek –

darknet market darknet drugs

Kxyuabind –

dark web marketplaces dark websites

MarkNOphodo –

darkmarket list darknet drugs

Pingcex –

dark web markets darknet market

Pingmok –

darknet markets links tor drug market

TolikFus –

dark market onion darknet markets onion address

DonDonabind –

dark market list dark market url

MarkNOTax –

darknet site dark web link

KxyuWaf –

dark market list dark market link

Kxyuabind –

dark websites darknet site

FNDavidInhek –

dark web sites darknet market list

RabyInhek –

dark market list darknet market lists

Pirojokshelp –

darkmarket url dark web market urls

Pingmok –

dark web marketplaces darkmarket list

DonDonWaf –

dark web link darknet markets url

TolikFus –

dark web drug marketplace dark market onion

Kxyuabind –

dark web marketplaces darknet markets links

Pirojokshelp –

darknet market list darknet drug links

Rabyporma –

dark market list dark market link

DonaldTax –

dark web drug marketplace darkmarket 2025

Donaldphodo –

dark web link darknet markets links

PirojokDet –

dark market list darknet markets onion

Kxyuabind –

darkmarkets dark web sites

Pirojokshelp –

dark web markets darknet market lists

DonDonabind –

darknet site dark web market

Pingmok –

dark market url darknet websites

Rabyporma –

darknet markets links dark web market urls

RabyInhek –

dark market link darkmarket list

Pingcex –

dark web market urls darknet sites

Pingmok –

darknet market darknet markets url

PirojokDet –

darkmarkets darknet drug market

Kxyuabind –

darknet markets onion darknet markets links

DonDonabind –

dark web markets darkmarket link

Pirojokshelp –

darknet markets url darkmarkets

MarkNOphodo –

darknet markets url onion dark website

FNDavidInhek –

dark web market links darkmarket list

Rabyporma –

tor drug market darkmarket list

Donaldphodo –

dark web link darknet drug market

KxyuWaf –

dark markets 2025 dark web market list

PirojokDet –

dark market onion dark market list

Kxyuabind –

darkmarket list darknet markets

DonDonWaf –

dark web market links onion dark website

FNDavidporma –

dark web markets tor drug market

Tolikplova –

darknet markets url darknet drug links

FNDavidInhek –

dark market 2025 darknet drug market

DonDonabind –

darknet links dark web market list

TolikFus –

darkmarkets dark market onion

DonaldTax –

dark markets darknet site

RabyInhek –

dark web market list darknet markets 2025

Donaldphodo –

dark web market links darknet markets onion

Pingcex –

dark markets dark market list

Pingmok –

darkmarket link darknet websites

FNDavidporma –

dark web market list dark market onion

Pirojokshelp –

dark websites darkmarket list

DonDonabind –

dark web marketplaces darknet markets onion address

TolikFus –

tor drug market darknet drug market

Pingmok –

darkmarket dark web marketplaces

WilliamIRcex –

dark websites darkmarket list

WilliamIRmok –

darknet markets onion address darknet markets

FNDavidporma –

darknet markets links dark market url

Kxyuabind –

dark web markets dark market link

MarkNOphodo –

darknet links dark market link

FNDavidInhek –

darkmarket list dark market onion

Pingmok –

dark websites darknet markets onion address

WilliamIRcex –

dark web marketplaces darknet sites

RabyInhek –

dark web market dark market 2025

MashaJip6968 –

XEvil6.0自动解决大多数类型的captchas,

包括这类验证码: ReCaptcha-2, ReCaptcha v.3, Google captcha, SolveMedia, BitcoinFaucet, Steam, +12k

+ hCaptcha, FC, ReCaptcha Enterprize 现在支持新的Xevil6.0!

1.) 快速,轻松

XEvil是世界上最快的验证码杀手。 它没有解决限制,没有线程数限制

2.) 几个Api支持

XEvil支持超过6种不同的全球知名API: 2Captcha, anti-captchas.com (antigate), RuCaptcha, death-by-captcha, etc.

只要通过HTTP请求发送您的验证码,因为您可以发送到任何一个服务-和XEvil将解决您的验证码!

因此,XEvil与数百个SEO/SMM/密码恢复/解析/发布/点击/加密货币/等应用程序兼容。

3.) 有用的支持和手册

购买后,您可以访问私人技术。支持论坛,维基,Skype/电报在线支持

开发人员将免费且非常快速地训练XEvil到您的验证码类型-只需向他们发送示例

4.) 如何免费试用XEvil完整版?

– 尝试在Google中搜索 “Home of XEvil”

– 您将找到Xevil用户打开端口80的Ip(点击任何IP以确保)

– 尝试通过2captcha API ino其中一个Ip发送您的captcha

– 如果你有坏的密钥错误,只需tru另一个IP

– 享受吧! 🙂

– (它不适用于hCaptcha!)

警告:免费XEvil演示不支持ReCaptcha,hCaptcha和大多数其他类型的captcha!

http://xrumersale.site/

PirojokDet –

darknet drugs darknet drug market

Kxyuabind –

darkmarket list bitcoin dark web

Tolikplova –

dark websites darknet websites

Pingcex –

darknet drug market dark web markets

TolikFus –

dark web marketplaces tor drug market

DonDonabind –

darkmarket list darknet market links

WilliamIRmok –

dark market darknet sites

FNDavidporma –

dark markets 2025 dark web link

MarkNOphodo –

darknet marketplace dark web market

Donaldphodo –

bitcoin dark web dark market link

RabyInhek –

dark web market links darkmarket link

FNDavidInhek –

darknet drugs darknet sites

Kxyuabind –

darkmarket darknet drug store

Pingcex –

dark web drug marketplace darknet markets

MarkNOphodo –

darknet markets 2025 onion dark website

Donaldphodo –

dark market dark market url

RabyInhek –

best darknet markets onion dark website

Kxyuabind –

dark market onion dark markets

Pingcex –

darknet links darknet markets links

Pingmok –

darknet markets onion darknet drug links

DonDonWaf –

darknet markets url dark web marketplaces

TolikFus –

darkmarket list dark web drug marketplace

DonDonabind –

best darknet markets darknet markets url

MarkNOTax –

dark web sites dark websites

WilliamIRmok –

darknet market links darknet marketplace

FNDavidporma –

darknet markets links darknet sites

MarkNOphodo –

darknet marketplace darknet markets links

FNDavidInhek –

darkmarket link darknet drug market

Pingcex –

dark web market links darknet market

KxyuWaf –

dark web drug marketplace dark web market links

Donaldphodo –

dark web markets onion dark website

Pirojokshelp –

dark web link dark web market urls

Tolikplova –

darknet markets dark web link

WilliamIRcex –

dark market url dark market onion

WilliamIRmok –

dark market 2025 dark market 2025

MarkNOTax –

darknet drug market dark market 2025

MarkNOphodo –

dark web market dark market onion

Pingmok –

darkmarket link darknet markets url

Donaldphodo –

dark market 2025 onion dark website

Pirojokshelp –

dark web market darknet markets url

Pingmok –

dark web link darknet markets onion address

WilliamIRmok –

dark markets 2025 dark web market links

MarkNOTax –

dark market link dark web market links

FNDavidInhek –

dark market darkmarket link

RabyInhek –

dark web markets dark web market list

TolikFus –

dark web drug marketplace dark web market links

DonDonabind –

darknet markets url dark market

WilliamIRmok –

darkmarkets darknet markets onion address

MarkNOTax –

darknet links onion dark website

Pirojokshelp –

darknet sites dark web market urls

Rabyporma –

darknet site dark web drug marketplace

RabyInhek –

dark web sites dark market list

Pingcex –

darknet drug store darknet markets

Pingmok –

darknet markets 2025 darknet markets onion

WilliamIRmok –

darkmarket list dark market onion

DonDonabind –

darknet site darkmarket 2025

TolikFus –

dark web link onion dark website

PirojokDet –

darknet drug links dark web sites

KxyuWaf –

darkmarket url darknet links

FNDavidInhek –

dark market 2025 dark market onion

WilliamIRcex –

darknet websites onion dark website

WilliamIRmok –

dark web market links dark web market links

DonDonWaf –

dark web market links dark market url

FNDavidporma –

darknet markets onion address dark market link

KxyuWaf –

tor drug market darknet marketplace

FNDavidInhek –

darkmarkets darknet drug store

Pingcex –

dark market link best darknet markets

Pingmok –

dark market darknet market list

Rabyporma –

dark web drug marketplace darknet markets url

WilliamIRcex –

dark web drug marketplace dark market

WilliamIRmok –

dark market url darknet market

TolikFus –

darknet websites onion dark website

Pingcex –

dark market list dark websites

Pingmok –

darkmarket 2025 darknet websites

FNDavidInhek –

dark websites dark market link

Pirojokshelp –

dark websites dark market list

RabyInhek –

darknet drug store darknet sites

WilliamIRcex –

dark market link darkmarket link

Pingcex –

darknet site darknet markets links

Tolikplova –

dark market dark market list

Pingmok –

darknet market list dark market link

DonDonabind –

dark web drug marketplace darkmarket

Kxyuabind –

bitcoin dark web dark market list

RabyInhek –

darknet markets onion dark market url

WilliamIRcex –

darknet websites darknet site

WilliamIRmok –

dark web market links darknet site

Pingcex –

darknet drug market darkmarket list

Pingmok –

darkmarket 2025 dark web market urls

DonDonabind –

darknet websites darknet markets links

FNDavidporma –

darknet markets links darknet market links

PirojokDet –

darknet websites darknet market list

DonaldTax –

darknet market list darknet links

WilliamIRcex –

darknet websites darknet drug market

Donaldphodo –

darknet marketplace dark market 2025

Pingmok –

dark web market urls dark websites

DonDonabind –

darknet drug links darknet links

TolikFus –

darkmarket darknet websites

FNDavidporma –

darkmarket list darknet websites

PirojokDet –

darknet websites darkmarket link

MarkNOTax –

dark web market list darkmarkets

Pirojokshelp –

dark web marketplaces darknet site

WilliamIRcex –

darknet markets url dark market onion

Pingcex –

bitcoin dark web darknet market list

DonaldTax –

darknet market lists dark web market

WilliamIRmok –

darknet markets dark market list

Pingmok –

dark market link darknet market

Donaldphodo –

dark markets 2025 darknet site

TolikFus –

dark web sites onion dark website

KxyuWaf –

dark markets 2025 darkmarket link

Pirojokshelp –

darknet markets darknet markets

Pingmok –

dark markets 2025 darknet market lists

Donaldphodo –

best darknet markets tor drug market

MarkNOTax –

dark web market links https://github.com/abacusdarknetlinkwrqqd/abacusdarknetlink – darkmarket url

FNDavidporma –

darkmarket https://github.com/abacusshop97c81/abacusshop – darknet drug market

FNDavidInhek –

dark web link https://github.com/abacusshop97c81/abacusshop – darkmarket url

WilliamIRmok –

darknet markets links https://github.com/darkwebwebsites/darkwebwebsites – dark web link

KxyuWaf –

dark market list https://github.com/abacusmarketurl7h9xj/abacusmarketurl – darknet links

MarkNOTax –

darknet drug market https://github.com/abacusdarknetlinkwrqqd/abacusdarknetlink – dark markets

Pirojokshelp –

dark web markets https://mydarknetmarketsurl.com – dark web market list

MarkNOphodo –

dark market list https://github.com/abacusdarknetlinkwrqqd/abacusdarknetlink – darknet site

Kxyuabind –

dark web market https://github.com/abacusmarketurl7h9xj/abacusmarketurl – darkmarket list

WilliamIRcex –

dark market 2025 https://github.com/darkwebwebsites/darkwebwebsites – darknet marketplace

WilliamIRmok –

dark web market https://github.com/darkwebwebsites/darkwebwebsites – darkmarkets

MashaJip4307 –

Xevil5.0自动解决大多数类型的captchas,

包括这类验证码: ReCaptcha-2, ReCaptcha-3, Google captcha, SolveMedia, BitcoinFaucet, Steam, +12000

+ hCaptcha, FC, ReCaptcha Enterprize 现在支持新的Xevil6.0!

1.) 快速,轻松

XEvil是世界上最快的验证码杀手。 它没有解决限制,没有线程数限制

2.) 几个Api支持

XEvil支持超过6种不同的全球知名API: 2Captcha, anti-captcha (antigate), RuCaptcha, death-by-captcha, etc.

只要通过HTTP请求发送您的验证码,因为您可以发送到任何一个服务-和XEvil将解决您的验证码!

因此,XEvil与数百个SEO/SMM/密码恢复/解析/发布/点击/加密货币/等应用程序兼容。

3.) 有用的支持和手册

购买后,您可以访问私人技术。支持论坛,维基,Skype/电报在线支持

开发人员将免费且非常快速地训练XEvil到您的验证码类型-只需向他们发送示例

4.) 如何免费试用XEvil完整版?

– 尝试在Google中搜索 “Home of XEvil”

– 您将找到Xevil用户打开端口80的Ip(点击任何IP以确保)

– 尝试通过2captcha API ino其中一个Ip发送您的captcha

– 如果你有坏的密钥错误,只需tru另一个IP

– 享受吧! 🙂

– (它不适用于hCaptcha!)

警告:免费XEvil演示不支持ReCaptcha,hCaptcha和大多数其他类型的captcha!

http://xrumersale.site/

WilliamIRcex –

darknet links https://github.com/darkwebwebsites/darkwebwebsites – darknet market lists

WilliamIRmok –

dark web marketplaces https://github.com/darkwebwebsites/darkwebwebsites – darkmarket 2025

MarkNOTax –

dark web markets https://github.com/abacusdarknetlinkwrqqd/abacusdarknetlink – darknet markets onion address

WilliamIRcex –

darknet drug market https://github.com/darkwebwebsites/darkwebwebsites – darknet drug links

Pirojokshelp –

darkmarket link https://mydarknetmarketsurl.com – darknet marketplace

FNDavidInhek –

dark web market list https://github.com/abacusshop97c81/abacusshop – dark market onion

WilliamIRmok –

dark market url https://github.com/darkwebwebsites/darkwebwebsites – darknet drugs

DonDonWaf –

darkmarket link https://github.com/nexusshopajlnb/nexusshop – dark market list

TolikFus –

darkmarket https://github.com/nexusdarknetmarketp0isi/nexusdarknetmarket – darknet marketplace

Pingmok –

darknet markets onion address https://github.com/nexusonion1b4tk/nexusonion – dark web drug marketplace

Rabyporma –

darknet markets 2025 https://github.com/abacusdarknetmarketfpyjk/abacusdarknetmarket – darkmarket 2025

RabyInhek –

dark market link https://github.com/abacusdarknetmarketfpyjk/abacusdarknetmarket – dark market

Kxyuabind –

tor drug market https://github.com/abacusmarketurl7h9xj/abacusmarketurl – darknet markets onion address

WilliamIRcex –

tor drug market https://github.com/darkwebwebsites/darkwebwebsites – darknet markets

FNDavidInhek –

darkmarket url https://github.com/abacusshop97c81/abacusshop – darkmarkets

WilliamIRmok –

darknet sites https://github.com/darkwebwebsites/darkwebwebsites – onion dark website

Pingmok –

dark market link https://github.com/nexusonion1b4tk/nexusonion – dark markets

DonDonWaf –

darkmarkets https://github.com/nexusshopajlnb/nexusshop – dark market onion

DonDonabind –

darknet markets links https://github.com/nexusshopajlnb/nexusshop – darkmarket url

KxyuWaf –

dark market list https://github.com/abacusmarketurl7h9xj/abacusmarketurl – darknet markets 2025

MarkNOTax –

darknet market list https://github.com/abacusdarknetlinkwrqqd/abacusdarknetlink – dark market onion

Pirojokshelp –

dark web link https://mydarknetmarketsurl.com – darknet drug links

MarkNOphodo –

darkmarket url https://github.com/abacusdarknetlinkwrqqd/abacusdarknetlink – darknet market links

RabyInhek –

darknet market lists https://github.com/abacusdarknetmarketfpyjk/abacusdarknetmarket – darknet market

FNDavidInhek –

dark web sites https://github.com/abacusshop97c81/abacusshop – darknet drug store

Pingmok –

dark web market list https://github.com/nexusonion1b4tk/nexusonion – darkmarkets

DonDonWaf –

dark market https://github.com/nexusshopajlnb/nexusshop – darknet marketplace

DonDonabind –

best darknet markets https://github.com/nexusshopajlnb/nexusshop – darkmarket list

KxyuWaf –

dark web drug marketplace https://github.com/abacusmarketurl7h9xj/abacusmarketurl – darkmarket

Pirojokshelp –

darknet marketplace https://mydarknetmarketsurl.com – dark web sites

MarkNOphodo –

dark market onion https://github.com/abacusdarknetlinkwrqqd/abacusdarknetlink – dark market 2025

FNDavidInhek –

darknet markets onion address https://github.com/abacusshop97c81/abacusshop – darkmarket link

RabyInhek –

darkmarket list https://github.com/abacusdarknetmarketfpyjk/abacusdarknetmarket – dark web markets

DonaldTax –

darknet markets url https://github.com/nexusdarknetmarketrtul8/nexusdarknetmarket – darknet market links

Donaldphodo –

darkmarket list https://github.com/nexusdarknetmarketrtul8/nexusdarknetmarket – dark market list

Tolikplova –

tor drug market https://github.com/nexusdarknetmarketp0isi/nexusdarknetmarket – darknet drug links

DonDonabind –

best darknet markets https://github.com/nexusshopajlnb/nexusshop – dark market

KxyuWaf –

dark market link https://github.com/abacusmarketurl7h9xj/abacusmarketurl – darknet markets onion

Pingcex –

dark market url https://github.com/nexusonion1b4tk/nexusonion – darkmarket url

Pirojokshelp –

darknet market https://mydarknetmarketsurl.com – darkmarket link

FNDavidporma –

darknet markets links https://github.com/abacusshop97c81/abacusshop – darknet drug links

WilliamIRmok –

dark web market urls https://github.com/darkwebwebsites/darkwebwebsites – dark web marketplaces

FNDavidInhek –

tor drug market https://github.com/abacusshop97c81/abacusshop – onion dark website

RabyInhek –

dark web markets https://github.com/abacusdarknetmarketfpyjk/abacusdarknetmarket – tor drug market

Donaldphodo –

best darknet markets https://github.com/nexusdarknetmarketrtul8/nexusdarknetmarket – onion dark website

Pingmok –

darknet markets https://github.com/nexusonion1b4tk/nexusonion – darknet market list

KxyuWaf –

darknet sites https://github.com/abacusmarketurl7h9xj/abacusmarketurl – tor drug market

PirojokDet –

darkmarket 2025 https://mydarknetmarketsurl.com – darknet markets onion address

Kxyuabind –

darknet drugs https://github.com/abacusmarketurl7h9xj/abacusmarketurl – darknet drug market

FNDavidInhek –

dark market list https://github.com/abacusshop97c81/abacusshop – darknet markets

WilliamIRmok –

best darknet markets https://github.com/darkwebwebsites/darkwebwebsites – dark market list

MarkNOphodo –

darknet markets url https://github.com/abacusdarknetlinkwrqqd/abacusdarknetlink – dark market onion

Rabyporma –

dark web drug marketplace https://github.com/abacusdarknetmarketfpyjk/abacusdarknetmarket – tor drug market

RabyInhek –

dark market https://github.com/abacusdarknetmarketfpyjk/abacusdarknetmarket – darknet markets

DonaldTax –

darknet site https://github.com/nexusdarknetmarketrtul8/nexusdarknetmarket – darknet drugs

Donaldphodo –

darkmarket 2025 https://github.com/nexusdarknetmarketrtul8/nexusdarknetmarket – dark web markets

Pingcex –

darkmarket list https://github.com/nexusonion1b4tk/nexusonion – darknet site

Pingmok –

darknet markets onion https://github.com/nexusonion1b4tk/nexusonion – dark web drug marketplace

DonDonWaf –

darknet markets url https://github.com/nexusshopajlnb/nexusshop – darknet links

Pirojokshelp –

dark web sites https://mydarknetmarketsurl.com – darknet drug store

WilliamIRmok –

dark web market urls https://github.com/darkwebwebsites/darkwebwebsites – tor drug market

RabyInhek –

dark market onion https://github.com/abacusdarknetmarketfpyjk/abacusdarknetmarket – darknet site

Donaldphodo –

dark market onion https://github.com/nexusdarknetmarketrtul8/nexusdarknetmarket – darknet drugs

Pingmok –

dark web markets https://github.com/nexusonion1b4tk/nexusonion – dark web market links

KxyuWaf –

darkmarket url https://github.com/abacusmarketurl7h9xj/abacusmarketurl – darknet site

TolikFus –

onion dark website https://github.com/nexusdarknetmarketp0isi/nexusdarknetmarket – dark web link

DonDonabind –

dark web link https://github.com/nexusshopajlnb/nexusshop – dark market link

Kxyuabind –

darknet market list https://github.com/abacusmarketurl7h9xj/abacusmarketurl – dark websites

FNDavidporma –

tor drug market https://github.com/abacusshop97c81/abacusshop – darknet market links

MarkNOphodo –

darknet site https://github.com/abacusdarknetlinkwrqqd/abacusdarknetlink – darknet markets links

WilliamIRmok –

dark web market links https://github.com/darkwebwebsites/darkwebwebsites – dark web markets

Rabyporma –

dark web markets https://github.com/abacusdarknetmarketfpyjk/abacusdarknetmarket – dark market link

Pingmok –

dark web sites https://github.com/nexusonion1b4tk/nexusonion – dark websites

RabyInhek –

darknet drug store https://github.com/abacusdarknetmarketfpyjk/abacusdarknetmarket – darkmarket

Donaldphodo –

darknet market https://github.com/nexusdarknetmarketrtul8/nexusdarknetmarket – dark market url

DonDonWaf –

bitcoin dark web https://github.com/nexusshopajlnb/nexusshop – darknet websites

Tolikplova –

dark market url https://github.com/nexusdarknetmarketp0isi/nexusdarknetmarket – darknet site

TolikFus –

best darknet markets https://github.com/nexusdarknetmarketp0isi/nexusdarknetmarket – darknet market lists

WilliamIRcex –

darkmarket list https://github.com/darkwebwebsites/darkwebwebsites – dark web drug marketplace

RabyInhek –

dark web marketplaces https://github.com/abacusdarknetmarketfpyjk/abacusdarknetmarket – dark web sites

Donaldphodo –

dark web market https://github.com/nexusdarknetmarketrtul8/nexusdarknetmarket – dark web market links

KxyuWaf –

dark web drug marketplace https://github.com/abacusmarketurl7h9xj/abacusmarketurl – bitcoin dark web

Pirojokshelp –

dark market onion https://mydarknetmarketsurl.com – darknet markets onion address

FNDavidporma –

dark web markets https://github.com/abacusshop97c81/abacusshop – darknet market

DonDonWaf –

dark web drug marketplace https://github.com/nexusshopajlnb/nexusshop – darknet market list

Tolikplova –

darknet marketplace https://github.com/nexusdarknetmarketp0isi/nexusdarknetmarket – darknet drug store

WilliamIRcex –

dark markets 2025 https://github.com/darkwebwebsites/darkwebwebsites – dark market

MarkNOphodo –

dark markets https://github.com/abacusdarknetlinkwrqqd/abacusdarknetlink – onion dark website

TolikFus –

darknet market list https://github.com/nexusdarknetmarketp0isi/nexusdarknetmarket – dark web market list

DonDonabind –

darknet markets 2025 https://github.com/nexusshopajlnb/nexusshop – dark web sites

WilliamIRmok –

dark web market https://github.com/darkwebwebsites/darkwebwebsites – darknet drug store

Pingmok –

dark market https://github.com/nexusonion1b4tk/nexusonion – dark market onion

Rabyporma –

dark web link https://github.com/abacusdarknetmarketfpyjk/abacusdarknetmarket – darkmarket url

DonaldTax –

darknet markets links https://github.com/nexusdarknetmarketrtul8/nexusdarknetmarket – darkmarkets

RabyInhek –

bitcoin dark web https://github.com/abacusdarknetmarketfpyjk/abacusdarknetmarket – dark market link

Kxyuabind –

darkmarket url https://github.com/abacusmarketurl7h9xj/abacusmarketurl – dark web market

Donaldphodo –

darknet market links https://github.com/nexusdarknetmarketrtul8/nexusdarknetmarket – best darknet markets

MarkNOphodo –

dark web link https://github.com/abacusdarknetlinkwrqqd/abacusdarknetlink – darknet markets onion

Pingcex –

darkmarket link https://github.com/nexusonion1b4tk/nexusonion – darknet drugs

Tolikplova –

darknet markets onion address https://github.com/nexusdarknetmarketp0isi/nexusdarknetmarket – dark web market urls

WilliamIRmok –

dark market onion https://github.com/darkwebwebsites/darkwebwebsites – darknet drug links

Pingmok –

dark web drug marketplace https://github.com/nexusonion1b4tk/nexusonion – darknet site

DonDonabind –

dark websites https://github.com/nexusshopajlnb/nexusshop – darknet market

PirojokDet –

darkmarket 2025 https://mydarknetmarketsurl.com – tor drug market

Pirojokshelp –

dark market https://mydarknetmarketsurl.com – darkmarket 2025

Donaldphodo –

darknet markets 2025 https://github.com/nexusdarknetmarketrtul8/nexusdarknetmarket – dark market url

WilliamIRcex –

dark web market list https://github.com/darkwebwebsites/darkwebwebsites – dark market onion

FNDavidInhek –

dark markets https://github.com/abacusshop97c81/abacusshop – darknet site

WilliamIRmok –

darknet market list https://github.com/darkwebwebsites/darkwebwebsites – darkmarket link

DonDonWaf –

dark web marketplaces https://github.com/nexusshopajlnb/nexusshop – darknet site

DonDonabind –

dark web market urls https://github.com/nexusshopajlnb/nexusshop – dark web market list

TolikFus –

dark market link https://github.com/nexusdarknetmarketp0isi/nexusdarknetmarket – dark market

KxyuWaf –

dark web drug marketplace https://github.com/abacusmarketurl7h9xj/abacusmarketurl – onion dark website

Pirojokshelp –

dark web market links https://mydarknetmarketsurl.com – tor drug market

Rabyporma –

darknet links https://github.com/abacusdarknetmarketfpyjk/abacusdarknetmarket – darknet markets url

FNDavidporma –

darknet markets https://github.com/abacusshop97c81/abacusshop – darkmarket link

MarkNOTax –

dark web link https://github.com/abacusdarknetlinkwrqqd/abacusdarknetlink – darknet markets onion

WilliamIRcex –

darknet links https://github.com/darkwebwebsites/darkwebwebsites – darkmarket

Donaldphodo –

dark market link https://github.com/nexusdarknetmarketrtul8/nexusdarknetmarket – darknet sites

MarkNOphodo –

darknet markets onion address https://github.com/abacusdarknetlinkwrqqd/abacusdarknetlink – darkmarket 2025

Tolikplova –

dark web market urls https://github.com/nexusdarknetmarketp0isi/nexusdarknetmarket – darkmarket 2025

DonDonabind –

bitcoin dark web https://github.com/nexusshopajlnb/nexusshop – darkmarket link

TolikFus –

darknet sites https://github.com/nexusdarknetmarketp0isi/nexusdarknetmarket – darkmarket link

KxyuWaf –

darknet sites https://github.com/abacusmarketurl7h9xj/abacusmarketurl – dark market 2025

PirojokDet –

dark market https://mydarknetmarketsurl.com – darknet markets url

Kxyuabind –

onion dark website https://github.com/abacusmarketurl7h9xj/abacusmarketurl – dark web sites

Pingmok –

darknet drug store https://github.com/nexusonion1b4tk/nexusonion – darknet markets

Rabyporma –

darkmarket list https://github.com/abacusdarknetmarketfpyjk/abacusdarknetmarket – dark web sites

WilliamIRcex –

darknet market list https://github.com/darkwebwebsites/darkwebwebsites – dark web sites

RabyInhek –

darknet markets onion https://github.com/abacusdarknetmarketfpyjk/abacusdarknetmarket – dark web drug marketplace

WilliamIRmok –

darknet marketplace https://github.com/darkwebwebsites/darkwebwebsites – dark web market list

Donaldphodo –

dark market 2025 https://github.com/nexusdarknetmarketrtul8/nexusdarknetmarket – darknet drug links

DonDonWaf –

darknet marketplace https://github.com/nexusshopajlnb/nexusshop – dark websites

DonDonabind –

dark web marketplaces https://github.com/nexusshopajlnb/nexusshop – darknet market links

TolikFus –

darknet market links https://github.com/nexusdarknetmarketp0isi/nexusdarknetmarket – darknet drug links

KxyuWaf –

darknet markets url https://github.com/abacusmarketurl7h9xj/abacusmarketurl – dark market link

Pingcex –

dark web market list https://github.com/nexusonion1b4tk/nexusonion – best darknet markets

PirojokDet –

darknet marketplace https://mydarknetmarketsurl.com – darknet drug market

Pirojokshelp –

dark market url https://mydarknetmarketsurl.com – dark market list

Kxyuabind –

darknet drug market https://github.com/abacusmarketurl7h9xj/abacusmarketurl – darknet market lists

PirojokDet –

dark web markets https://mydarknetmarketsurl.com – best darknet markets

Pirojokshelp –

darknet market links https://mydarknetmarketsurl.com – darknet markets links

FNDavidporma –

dark web market list https://github.com/abacusshop97c81/abacusshop – dark market list

Kxyuabind –

darknet links https://github.com/abacusmarketurl7h9xj/abacusmarketurl – dark web marketplaces

FNDavidInhek –

onion dark website https://github.com/abacusshop97c81/abacusshop – dark market list

Kxyuabind –

darkmarket url https://github.com/darkwebwebsites/darkwebwebsites – darknet drugs

FNDavidporma –

darknet drug market https://github.com/abacusshop97c81/abacusshop – darknet sites

KxyuWaf –

darknet drugs https://github.com/darkwebwebsites/darkwebwebsites – dark market onion

Kxyuabind –

darknet drug links https://github.com/abacusmarketurl7h9xj/abacusmarketurl – dark web markets

Kxyuabind –

darkmarket list https://github.com/abacusmarketurl7h9xj/abacusmarketurl – dark markets 2025

Kxyuabind –

tor drug market https://github.com/abacusmarketurl7h9xj/abacusmarketurl – bitcoin dark web

KxyuWaf –

darknet drug market https://github.com/abacusmarketurl7h9xj/abacusmarketurl – darkmarket url

Rabyporma –

dark web market https://github.com/abacusdarknetmarketfpyjk/abacusdarknetmarket – darknet websites

MarkNOTax –

darknet markets 2025 https://github.com/abacusdarknetlinkwrqqd/abacusdarknetlink – darknet market list

MarkNOphodo –

darkmarket list https://github.com/abacusdarknetlinkwrqqd/abacusdarknetlink – onion dark website

DonDonWaf –

darknet market list https://github.com/nexusshopajlnb/nexusshop – darknet drug store

DonDonabind –

dark markets https://github.com/nexusonion1b4tk/nexusonion – darkmarket

Donaldphodo –

darknet drug market https://github.com/nexusdarknetmarketrtul8/nexusdarknetmarket – darkmarket 2025

Tolikplova –

dark websites https://github.com/nexusdarknetmarketp0isi/nexusdarknetmarket – dark market url

KxyuWaf –

dark market 2025 https://github.com/abacusmarketurl7h9xj/abacusmarketurl – darknet markets 2025

Kxyuabind –

dark market 2025 https://github.com/abacusmarketurl7h9xj/abacusmarketurl – darknet drug store

TolikFus –

dark web market list https://github.com/nexusdarknetmarketp0isi/nexusdarknetmarket – darknet drugs

PirojokDet –

darknet marketplace https://mydarknetmarketsurl.com – dark market

Pirojokshelp –

dark market list https://mydarknetmarketsurl.com – dark market url

JayuWaf –

bitcoin dark web https://github.com/darkwebwebsites/darkwebwebsites – darknet markets links

FNDavidporma –

dark web market list https://github.com/abacusshop97c81/abacusshop – darknet markets onion address

Jayuabind –

darknet markets https://github.com/darkwebwebsites/darkwebwebsites – dark websites

MarkNOphodo –

dark market https://github.com/abacusdarknetlinkwrqqd/abacusdarknetlink – dark web market

RabyInhek –

tor drug market https://github.com/abacusdarknetmarketfpyjk/abacusdarknetmarket – dark market link

DonDonWaf –

dark market link https://github.com/nexusshopajlnb/nexusshop – dark market url

DonaldTax –

dark web marketplaces https://github.com/nexusdarknetmarketrtul8/nexusdarknetmarket – dark market list

DonDonabind –

darkmarket link https://github.com/nexusonion1b4tk/nexusonion – dark market url

Kxyuabind –

dark web sites https://github.com/abacusmarketurl7h9xj/abacusmarketurl – dark market 2025

Donaldphodo –

dark web markets https://github.com/nexusdarknetmarketrtul8/nexusdarknetmarket – darknet drug links

Tolikplova –

darknet market links https://github.com/nexusdarknetmarketp0isi/nexusdarknetmarket – darknet links

Pirojokshelp –

dark markets https://mydarknetmarketsurl.com – dark web market links

TolikFus –

tor drug market https://github.com/nexusdarknetmarketp0isi/nexusdarknetmarket – dark market onion

FNDavidporma –

darkmarket 2025 https://github.com/abacusshop97c81/abacusshop – dark markets

RabyInhek –

darknet markets 2025 https://github.com/abacusdarknetmarketfpyjk/abacusdarknetmarket – dark web link

Kxyuabind –

dark market url https://github.com/abacusmarketurl7h9xj/abacusmarketurl – dark markets

DonDonWaf –

darknet links https://github.com/nexusonion1b4tk/nexusonion – dark web market links

DonDonabind –

tor drug market https://github.com/nexusshopajlnb/nexusshop – darknet websites

Pirojokshelp –

dark market onion https://mydarknetmarketsurl.com – dark web market list

DonDonabind –

dark web market https://github.com/nexusonion1b4tk/nexusonion – darknet drug links

Donaldphodo –

dark markets https://github.com/nexusdarknetmarketrtul8/nexusdarknetmarket – darkmarket url

TolikFus –

darknet drug store https://github.com/nexusdarknetmarketp0isi/nexusdarknetmarket – bitcoin dark web

FNDavidInhek –

darknet market lists https://github.com/abacusshop97c81/abacusshop – darkmarkets

MarkNOphodo –

darkmarket list https://github.com/abacusdarknetlinkwrqqd/abacusdarknetlink – darknet market list

Rabyporma –

darknet market lists https://github.com/abacusdarknetmarketfpyjk/abacusdarknetmarket – dark market link

RabyInhek –

darknet links https://github.com/abacusdarknetmarketfpyjk/abacusdarknetmarket – dark web drug marketplace

Pirojokshelp –

tor drug market https://mydarknetmarketsurl.com – bitcoin dark web

JayuWaf –

darknet drug links https://github.com/darkwebwebsites/darkwebwebsites – best darknet markets

DonDonabind –

darkmarket url https://github.com/nexusshopajlnb/nexusshop – dark markets

FNDavidInhek –

darknet markets onion https://github.com/abacusshop97c81/abacusshop – darknet links

Donaldphodo –

tor drug market https://github.com/nexusdarknetmarketrtul8/nexusdarknetmarket – darknet markets links

TolikFus –

darknet site https://github.com/nexusdarknetmarketp0isi/nexusdarknetmarket – onion dark website

Rabyporma –

darknet sites https://github.com/abacusdarknetmarketfpyjk/abacusdarknetmarket – dark web drug marketplace

RabyInhek –

darknet drug market https://github.com/abacusdarknetmarketfpyjk/abacusdarknetmarket – darknet links

Kxyuabind –

darknet market list https://github.com/abacusmarketurl7h9xj/abacusmarketurl – bitcoin dark web

PirojokDet –

dark web market https://mydarknetmarketsurl.com – best darknet markets

Pirojokshelp –

darknet drug market https://mydarknetmarketsurl.com – dark market link

FNDavidporma –

darknet markets onion address https://github.com/abacusshop97c81/abacusshop – dark web market urls

JayuWaf –

dark market onion https://github.com/darkwebwebsites/darkwebwebsites – tor drug market

DonDonWaf –

darknet sites https://github.com/nexusshopajlnb/nexusshop – bitcoin dark web

Jayuabind –

dark markets 2025 https://github.com/darkwebwebsites/darkwebwebsites – dark web sites

DonDonabind –

darknet sites https://github.com/nexusshopajlnb/nexusshop – dark market url

DonaldTax –

darknet sites https://github.com/nexusdarknetmarketrtul8/nexusdarknetmarket – darkmarket 2025

DonDonabind –

darknet drug links https://github.com/nexusonion1b4tk/nexusonion – darknet drugs

Donaldphodo –

darknet websites https://github.com/nexusdarknetmarketrtul8/nexusdarknetmarket – dark market list

TolikFus –

darkmarket https://github.com/nexusdarknetmarketp0isi/nexusdarknetmarket – dark web sites

Kxyuabind –

dark web marketplaces https://github.com/abacusmarketurl7h9xj/abacusmarketurl – dark web drug marketplace

PirojokDet –

dark markets https://mydarknetmarketsurl.com – darkmarkets

RabyInhek –

dark web market links https://github.com/abacusdarknetmarketfpyjk/abacusdarknetmarket – bitcoin dark web

Pirojokshelp –

darkmarket 2025 https://mydarknetmarketsurl.com – dark websites

JayuWaf –

dark market onion https://github.com/darkwebwebsites/darkwebwebsites – darknet links

DonDonWaf –

dark market url https://github.com/nexusshopajlnb/nexusshop – dark web market links

MarkNOTax –

bitcoin dark web https://github.com/abacusdarknetlinkwrqqd/abacusdarknetlink – dark web markets

DonDonabind –

darkmarket link https://github.com/nexusshopajlnb/nexusshop – darknet marketplace

DonaldTax –

dark web market list https://github.com/nexusdarknetmarketrtul8/nexusdarknetmarket – darknet drugs

DonDonabind –

darknet sites https://github.com/nexusonion1b4tk/nexusonion – darknet market list

Donaldphodo –

darknet websites https://github.com/nexusdarknetmarketrtul8/nexusdarknetmarket – darknet market links

TolikFus –

darknet market links https://github.com/nexusdarknetmarketp0isi/nexusdarknetmarket – darknet market list

Kxyuabind –

dark markets https://github.com/abacusmarketurl7h9xj/abacusmarketurl – darknet market lists

PirojokDet –

dark market url https://mydarknetmarketsurl.com – darkmarket url

Rabyporma –

darknet markets 2025 https://github.com/abacusdarknetmarketfpyjk/abacusdarknetmarket – darknet markets links

Pirojokshelp –

dark websites https://mydarknetmarketsurl.com – darkmarket list

RabyInhek –

darknet marketplace https://github.com/abacusdarknetmarketfpyjk/abacusdarknetmarket – dark market 2025

FNDavidporma –

darknet markets links https://github.com/abacusshop97c81/abacusshop – dark web market links

Jayuabind –

dark market onion https://github.com/darkwebwebsites/darkwebwebsites – dark web market urls

MarkNOphodo –

darknet websites https://github.com/abacusdarknetlinkwrqqd/abacusdarknetlink – darknet drug links

DonDonWaf –

dark market https://github.com/nexusshopajlnb/nexusshop – dark market url

DonDonabind –

dark market url https://github.com/nexusshopajlnb/nexusshop – darknet markets 2025

DonDonWaf –

darknet markets onion https://github.com/nexusonion1b4tk/nexusonion – darknet drugs

Tolikplova –

dark market https://github.com/nexusdarknetmarketp0isi/nexusdarknetmarket – darknet market

TolikFus –

onion dark website https://github.com/nexusdarknetmarketp0isi/nexusdarknetmarket – darknet drug links

Kxyuabind –

dark markets https://github.com/abacusmarketurl7h9xj/abacusmarketurl – darknet drug store

PirojokDet –

darknet sites https://mydarknetmarketsurl.com – darknet drug links

Rabyporma –

bitcoin dark web https://github.com/abacusdarknetmarketfpyjk/abacusdarknetmarket – darknet drug market

Pirojokshelp –

dark web drug marketplace https://mydarknetmarketsurl.com – darknet drug links

RabyInhek –

darknet market links https://github.com/abacusdarknetmarketfpyjk/abacusdarknetmarket – dark web market links

Jayuabind –

darkmarket url https://github.com/darkwebwebsites/darkwebwebsites – dark web drug marketplace

MarkNOphodo –

darknet drug market https://github.com/abacusdarknetlinkwrqqd/abacusdarknetlink – dark web markets

DonDonWaf –

darknet markets links https://github.com/nexusshopajlnb/nexusshop – onion dark website

DonDonabind –

dark websites https://github.com/nexusshopajlnb/nexusshop – onion dark website

DonDonWaf –

darkmarket url https://github.com/nexusonion1b4tk/nexusonion – darknet markets

KxyuWaf –

dark market url https://github.com/abacusmarketurl7h9xj/abacusmarketurl – darknet drug market

DonaldTax –

darknet markets https://github.com/nexusdarknetmarketrtul8/nexusdarknetmarket – darkmarket 2025

TolikFus –

darkmarket link https://github.com/nexusdarknetmarketp0isi/nexusdarknetmarket – bitcoin dark web

PirojokDet –

darkmarket 2025 https://mydarknetmarketsurl.com – dark market link

Pirojokshelp –

dark web sites https://mydarknetmarketsurl.com – darknet markets onion

FNDavidporma –

dark market list https://github.com/abacusshop97c81/abacusshop – onion dark website

FNDavidInhek –

darknet drug market https://github.com/abacusshop97c81/abacusshop – darkmarket 2025

Jayuabind –

darknet websites https://github.com/darkwebwebsites/darkwebwebsites – darknet drug market

RabyInhek –

darknet websites https://github.com/abacusdarknetmarketfpyjk/abacusdarknetmarket – dark market list

MarkNOphodo –

dark web markets https://github.com/abacusdarknetlinkwrqqd/abacusdarknetlink – darkmarket link

DonDonWaf –

darkmarkets https://github.com/nexusshopajlnb/nexusshop – best darknet markets

KxyuWaf –

dark web market list https://github.com/abacusmarketurl7h9xj/abacusmarketurl – darknet market lists

DonDonWaf –

dark web link https://github.com/nexusonion1b4tk/nexusonion – dark web markets

DonDonabind –

dark markets 2025 https://github.com/nexusonion1b4tk/nexusonion – dark markets 2025

PirojokDet –

darknet markets links https://mydarknetmarketsurl.com – dark market link

TolikFus –

dark market url https://github.com/nexusdarknetmarketp0isi/nexusdarknetmarket – dark web market list

Pirojokshelp –

darknet market lists https://mydarknetmarketsurl.com – darknet links

FNDavidporma –

dark market list https://github.com/abacusshop97c81/abacusshop – darknet market lists

FNDavidInhek –

best darknet markets https://github.com/abacusshop97c81/abacusshop – darknet market lists

MarkNOTax –

darkmarket url https://github.com/abacusdarknetlinkwrqqd/abacusdarknetlink – darkmarket url

Rabyporma –

dark web markets https://github.com/abacusdarknetmarketfpyjk/abacusdarknetmarket – dark web market links

RabyInhek –

dark web market urls https://github.com/abacusdarknetmarketfpyjk/abacusdarknetmarket – dark market

Kxyuabind –

darknet markets 2025 https://github.com/abacusmarketurl7h9xj/abacusmarketurl – darknet markets onion

DonDonabind –

darkmarket 2025 https://github.com/nexusshopajlnb/nexusshop – dark markets

DonDonWaf –

dark web sites https://github.com/nexusonion1b4tk/nexusonion – darknet market lists

PirojokDet –

darknet site https://mydarknetmarketsurl.com – best darknet markets

DonaldTax –

darknet markets onion address https://github.com/nexusdarknetmarketrtul8/nexusdarknetmarket – darkmarket 2025

Pirojokshelp –

dark web markets https://mydarknetmarketsurl.com – darkmarket url

DonDonabind –

darknet markets url https://github.com/nexusonion1b4tk/nexusonion – dark websites

FNDavidInhek –

darknet market links https://github.com/abacusshop97c81/abacusshop – dark web sites

MarkNOTax –

darknet drug store https://github.com/abacusdarknetlinkwrqqd/abacusdarknetlink – darkmarket url

MarkNOphodo –

dark market 2025 https://github.com/abacusdarknetlinkwrqqd/abacusdarknetlink – darknet drug store

Rabyporma –

darknet market links https://github.com/abacusdarknetmarketfpyjk/abacusdarknetmarket – dark web drug marketplace

RabyInhek –

dark markets 2025 https://github.com/abacusdarknetmarketfpyjk/abacusdarknetmarket – darknet drug market

DonDonWaf –

darknet drug store https://github.com/nexusshopajlnb/nexusshop – dark web markets

DonDonabind –

dark web market https://github.com/nexusshopajlnb/nexusshop – dark web market

PirojokDet –

darknet websites https://mydarknetmarketsurl.com – darknet sites

FNDavidporma –

dark market link https://github.com/abacusshop97c81/abacusshop – dark web market

MarkNOTax –

darknet markets 2025 https://github.com/abacusdarknetlinkwrqqd/abacusdarknetlink – dark web market

DonDonabind –

best darknet markets https://github.com/nexusonion1b4tk/nexusonion – dark market 2025

Donaldphodo –

darkmarket url https://github.com/nexusdarknetmarketrtul8/nexusdarknetmarket – darkmarket url

TolikFus –

dark web markets https://github.com/nexusdarknetmarketp0isi/nexusdarknetmarket – darknet markets links

RabyInhek –

dark web drug marketplace https://github.com/abacusdarknetmarketfpyjk/abacusdarknetmarket – bitcoin dark web

KxyuWaf –

darknet market list https://github.com/abacusmarketurl7h9xj/abacusmarketurl – onion dark website

Kxyuabind –

darknet market links https://github.com/abacusmarketurl7h9xj/abacusmarketurl – dark markets

PirojokDet –

bitcoin dark web https://mydarknetmarketsurl.com – dark web sites

Pirojokshelp –

dark markets https://mydarknetmarketsurl.com – darknet sites

JayuWaf –

bitcoin dark web https://github.com/darkwebwebsites/darkwebwebsites – darknet links

FNDavidInhek –

dark web market list https://github.com/abacusshop97c81/abacusshop – dark web link

MarkNOTax –

darknet markets onion https://github.com/abacusdarknetlinkwrqqd/abacusdarknetlink – darknet marketplace

Donaldphodo –

onion dark website https://github.com/nexusdarknetmarketrtul8/nexusdarknetmarket – dark web drug marketplace

TolikFus –

darknet links https://github.com/nexusdarknetmarketp0isi/nexusdarknetmarket – darknet markets

RabyInhek –

darknet markets 2025 https://github.com/abacusdarknetmarketfpyjk/abacusdarknetmarket – tor drug market

Kxyuabind –

dark market list https://github.com/abacusmarketurl7h9xj/abacusmarketurl – darknet drug links

DonDonWaf –

dark markets 2025 https://github.com/nexusshopajlnb/nexusshop – dark markets 2025

Pirojokshelp –

best darknet markets https://mydarknetmarketsurl.com – best darknet markets

DonDonabind –

darkmarket link https://github.com/nexusshopajlnb/nexusshop – darkmarket

MarkNOTax –

dark market link https://github.com/abacusdarknetlinkwrqqd/abacusdarknetlink – darknet drug market

MarkNOphodo –

darknet market list https://github.com/abacusdarknetlinkwrqqd/abacusdarknetlink – darkmarket list

DonDonabind –

darkmarket url https://github.com/nexusonion1b4tk/nexusonion – dark markets 2025

Donaldphodo –

darkmarket 2025 https://github.com/nexusdarknetmarketrtul8/nexusdarknetmarket – tor drug market

TolikFus –

darknet market list https://github.com/nexusdarknetmarketp0isi/nexusdarknetmarket – darknet markets onion address

KxyuWaf –

dark web market urls https://github.com/abacusmarketurl7h9xj/abacusmarketurl – darknet drug store

Rabyporma –

darkmarket 2025 https://github.com/abacusdarknetmarketfpyjk/abacusdarknetmarket – darkmarket list

RabyInhek –

darknet drug links https://github.com/abacusdarknetmarketfpyjk/abacusdarknetmarket – dark web markets

Pirojokshelp –

dark web market urls https://mydarknetmarketsurl.com – dark web market urls

JayuWaf –

darknet marketplace https://github.com/darkwebwebsites/darkwebwebsites – darknet markets onion

MarkNOphodo –

darknet markets https://github.com/abacusdarknetlinkwrqqd/abacusdarknetlink – dark web market list

DonDonWaf –

darkmarkets https://github.com/nexusonion1b4tk/nexusonion – darknet marketplace

DonDonabind –

best darknet markets https://github.com/nexusonion1b4tk/nexusonion – darknet site

Kxyuabind –

darknet markets links https://github.com/abacusmarketurl7h9xj/abacusmarketurl – darknet markets links

Rabyporma –

darknet market links https://github.com/abacusdarknetmarketfpyjk/abacusdarknetmarket – darknet market list

RabyInhek –

darknet websites https://github.com/abacusdarknetmarketfpyjk/abacusdarknetmarket – darkmarket url

DonDonWaf –

dark markets 2025 https://github.com/nexusshopajlnb/nexusshop – darknet drug store

KxyuWaf –

tor drug market https://github.com/abacusmarketurl7h9xj/abacusmarketurl – darknet drug store

Kxyuabind –

onion dark website https://github.com/abacusmarketurl7h9xj/abacusmarketurl – darkmarket link

TolikFus –

darknet sites https://github.com/nexusdarknetmarketp0isi/nexusdarknetmarket – darknet site

RabyInhek –

darknet drug market https://github.com/abacusdarknetmarketfpyjk/abacusdarknetmarket – dark web market links

DonDonWaf –

darkmarket url https://github.com/nexusshopajlnb/nexusshop – best darknet markets

DonDonWaf –

darknet markets onion https://github.com/nexusonion1b4tk/nexusonion – dark markets

Rabyporma –

dark market 2025 https://github.com/abacusdarknetmarketfpyjk/abacusdarknetmarket – dark market 2025

DonDonWaf –

darknet links https://github.com/nexusshopajlnb/nexusshop – dark market url

Donaldphodo –

dark market link https://github.com/nexusdarknetmarketrtul8/nexusdarknetmarket – dark market 2025

Rabyporma –

darknet websites https://github.com/abacusdarknetmarketfpyjk/abacusdarknetmarket – dark market 2025

RabyInhek –

dark market onion https://github.com/abacusdarknetmarketfpyjk/abacusdarknetmarket – darkmarket 2025

DonDonWaf –

darkmarket url https://github.com/nexusshopajlnb/nexusshop – darknet markets

DonDonabind –

darknet markets links https://github.com/nexusshopajlnb/nexusshop – darknet links

DonaldTax –

darknet site https://github.com/nexusdarknetmarketrtul8/nexusdarknetmarket – dark web drug marketplace

Tolikplova –

tor drug market https://github.com/nexusdarknetmarketp0isi/nexusdarknetmarket – darkmarket link

DonaldTax –

dark market list https://github.com/nexusdarknetmarketrtul8/nexusdarknetmarket – best darknet markets

Tolikplova –

darknet markets onion https://github.com/nexusdarknetmarketp0isi/nexusdarknetmarket – dark market url

Rabyporma –

dark web sites https://github.com/abacusdarknetmarketfpyjk/abacusdarknetmarket – darkmarket 2025

DonDonWaf –

dark web market urls https://github.com/nexusshopajlnb/nexusshop – dark web sites

Tolikplova –

dark web market urls https://github.com/nexusdarknetmarketp0isi/nexusdarknetmarket – darknet market links

DonDonWaf –

darkmarket link https://github.com/nexusshopajlnb/nexusshop – darknet market links

DonDonWaf –

darknet drug links https://github.com/nexusshopajlnb/nexusshop – dark web marketplaces

DonDonabind –

best darknet markets https://github.com/nexusshopajlnb/nexusshop – darknet drug store

Rabyporma –

dark market list https://github.com/abacusdarknetmarketfpyjk/abacusdarknetmarket – dark market link

Donaldphodo –

darknet markets url https://github.com/nexusdarknetmarketrtul8/nexusdarknetmarket – darknet drug market

DonDonWaf –

dark market 2025 https://github.com/nexusshopajlnb/nexusshop – darknet markets 2025

RabyInhek –

darknet markets onion https://github.com/abacusdarknetmarketfpyjk/abacusdarknetmarket – darknet sites

DonaldTax –

dark web sites https://github.com/nexusdarknetmarketrtul8/nexusdarknetmarket – darknet drug market

Rabyporma –

dark web link https://github.com/abacusdarknetmarketfpyjk/abacusdarknetmarket – dark web market links

DonDonWaf –

darknet drug links https://github.com/nexusshopajlnb/nexusshop – darknet markets links

DonDonWaf –

darkmarket link https://github.com/nexusshopajlnb/nexusshop – darknet markets url

DonaldTax –

darkmarket https://github.com/nexusdarknetmarketrtul8/nexusdarknetmarket – darknet market lists

TolikFus –

dark market link https://github.com/nexusdarknetmarketp0isi/nexusdarknetmarket – dark web markets

Rabyporma –

dark web marketplaces https://github.com/abacusdarknetmarketfpyjk/abacusdarknetmarket – onion dark website

DonDonWaf –

dark web market list https://github.com/nexusshopajlnb/nexusshop – darknet market list

Rabyporma –

darknet market https://github.com/abacusdarknetmarketfpyjk/abacusdarknetmarket – darkmarket url

Rabyporma –

darknet markets url https://github.com/abacusdarknetmarketfpyjk/abacusdarknetmarket – dark markets 2025

DonDonWaf –

darknet markets 2025 https://github.com/nexusonion1b4tk/nexusonion – dark websites

DonDonWaf –

darknet websites https://github.com/nexusshopajlnb/nexusshop – dark web drug marketplace

DonDonWaf –

darknet site https://github.com/nexusshopajlnb/nexusshop – darkmarket link

Rabyporma –

darknet drug market https://github.com/abacusdarknetmarketfpyjk/abacusdarknetmarket – darknet drug links

DonDonWaf –

dark web marketplaces https://github.com/nexusshopajlnb/nexusshop – dark web market list

Rabyporma –

dark market url https://github.com/abacusdarknetmarketfpyjk/abacusdarknetmarket – bitcoin dark web

DonDonWaf –

dark web sites https://github.com/nexusonion1b4tk/nexusonion – darkmarket list

Rabyporma –

dark web markets https://github.com/abacusdarknetmarketfpyjk/abacusdarknetmarket – darkmarkets

Terrellzig –

dark web market list darkmarket list [url=https://github.com/abacusmarketttdz7/abacusmarket ]dark web market urls [/url]

TimothyJap –

darknet market list dark market link [url=https://github.com/abacusmarketurld3lxg/abacusmarketurl ]darknet market [/url]

Williamsnony –

dark markets 2025 darkmarket [url=https://github.com/nexusmarketurlolt9d/nexusmarketurl ]dark web market [/url]

DonDonWaf –

dark web market links https://github.com/darkwebsitesyhshv/darkwebsites – darknet market links

DonDonabind –

dark web sites https://github.com/nexusdarknetmarketrtul8/nexusdarknetmarket – dark web market

Tolikplova –

darknet market links https://github.com/abacusurlxllh4/abacusurl – darknet market

TolikFus –

darknet markets onion https://github.com/abacusdarknetlinkwrqqd/abacusdarknetlink – darkmarket

DonaldTax –

dark web market links https://github.com/nexusdarknetut09h/nexusdarknet – darkmarket url

RabyInhek –

dark web market https://github.com/nexusmarketsjb3g/nexusmarket – dark markets

TolikFus –

darkmarket link https://github.com/abacusurlxllh4/abacusurl – dark market link

Rabyporma –

darkmarket link https://github.com/nexusdarkneturluoxgs/nexusdarkneturl – darkmarket url

DonaldTax –

dark market 2025 https://github.com/nexusonion1b4tk/nexusonion – dark market onion

DonDonWaf –

darknet markets onion address https://github.com/aresdarknetlinky8alb/aresdarknetlink – darknet drug store

DonDonWaf –

darknet markets url https://github.com/nexusdarknetmarketp0isi/nexusdarknetmarket – dark market onion

DonDonabind –

darkmarket link https://github.com/nexusshopajlnb/nexusshop – dark market url

Tolikplova –

darknet drugs https://github.com/abacuslink6ekdd/abacuslink – bitcoin dark web

TolikFus –

darknet markets url https://github.com/abacusdarknetlinkwrqqd/abacusdarknetlink – darknet markets onion address

DonaldTax –

darknet site https://github.com/nexusmarketlinkxgjgk/nexusmarketlink – darkmarkets

Rabyporma –